For pumps conveying medium containing solid particle, for example slurry pumps, etc., IPT can predict the wear area and wear rate inside the pump through numerical simulation and material testing. Based on the predicted results, adopt the optimal laser coating scheme to increase the service life of the pump and reduce the cost of use.

n The pump working under impurity particle condition has a long service life and high reliability

n The product meets the requirements of service life and is affordable

n Quantitatively predict the wear area and wear rate inside the impeller

n HVOF supersonic flame spraying treatment is adopted in the predicted wear area to meet the user's requirements for product service life and reduce costs for users

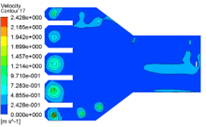

Velocity Vector Distribution of Sea Water Pump

Application of “AWS SFA5.14 ERNiCrMo-16” Corrosion Resistant Overlay Alloy

n Corrosion analysis of large and complex geometric structures using three-dimensional boundary element method

n Research and development of unique corrosion-resistant alloy coatings

n Conduct immersion test using seawater to verify the corrosion resistance of the pump

n Determine suitable materials and environment, apply anti-corrosion technology to ensure long-term reliability of the pump

n Repair damaged pump components through technologies such as Stellite welding and ceramic spraying, and replace parts to extend the service life of the pump

n In addition to seawater pumps, it also helps ensure reliability for use in chemical plants and oil and gas pumps

n High reliability products

n The best anti-corrosion measures,including maintenance based on extended service life

Accurate diagnosis and solution for product degradation