The DCSK series is BB5 multistage horizontal, double casing with radial split outer casing and axial split inner casing,back-to-back arranged Impellers. With the latest edition of API 610 and ISO 13709. The DCSK pump can be used for transporting a variety of clean or mircorpartical liquid, suitable for high temperature, high pressure, flammable, explosive medium Conditions.

The barrel and suction/discharge nozzle flange are forged,can bear higher pressure,optional side-side, side-top nozzles on forged barrel;The inner case can be extracted from barrel, easy to repair and maintain;The inner case is horizontally split for easy assembly;The impeller is arranged back-to-back, and the axial force of the rotor is self-balanced;Ball radial and 7300 series thrust bearings are standard.

Pressure lubricated sleeve/pivot shoe bearings are optional;Seal chamber meets API682 requirements; The high standardization design not only reduces inventory costs but also achieves the maximum interchangeability of components, thereby reducing the operating costs of the equipment throughout its life cycle.

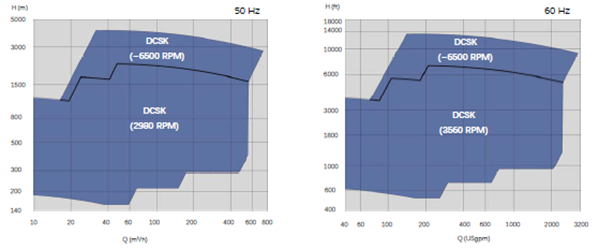

Capacities up to 1000 m³/h

Heads up to 7000 m

Pressures up to 420 bar

Temperatures -80 to 425°C

• Oil & Gas

• Petrochemical

• Power Generation

• Coal chemical industry

• Water and Wastewater

• General industry

• Fertilizers