The LDBA process pumps are specified wherever limited NPSH is available, either due to system constraints or liquids operating near their vapor pressure. NPSH requirements of the pump are met by simply adjusting the length of the pump and can. Typical applications include liquefied petroleum gas booster, cryogenics as well as general refining and other medium to high pressure applications.

The LDBA is a vertical turbine, often with suction can, that is built along ISO 13709 (API 610) guidelines. ISO 13709 (API 610) Type VS6 construction is most common but LDBA pumps may be furnished for sump cover or tank mounting in VS1 configuration. It is available in a wide array of sizes, stage counts, and configurations depending upon application and customer specified requirements. A variety of material combinations are available. The pump stages are typically known for their high head per stage which results in fewer stages and a shorter pump. For applications where high axial thrust is generated, a balance drum is offered to reduce thrust load. Column bushings are PEEK and bearing spacing meets ISO 13709 (API 610) requirements.

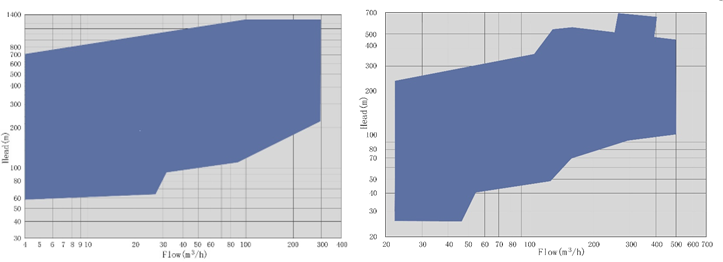

Capacities up to 550 m³/h

Heads up to 1000 m

Pressures up to 100 bar

Temperatures up to 180°C

• Oil and Gas

• Hydrocarbon Processing

• Pulp and Paper

• Power Generation

• General Industry

• Chemical Process Industry

• Water and Wastewater